As a small business owner, inventory is the most valuable and important asset of your retail store. Understanding this major line item on your balance sheet, and how to effectively manage inventory with POS inventory software is essential to surviving the first year of business and thriving in years to come.

Inventory can be classified into four categories: raw materials, work-in-progress, MRO (maintenance, repair, and operating), and finished goods. Finished goods are products that are ready to be sold to your customers and are the type most found in retail environments. While this is the most straightforward type of inventory, there is still a multitude of factors to consider when keeping inventory at just the right levels to maximize profitability.

Inventory management involves understanding your store’s resources, customer base, vendors, and the overall market to ensure the optimal type and quantity of products are available on store shelves when customers are looking to purchase while also minimizing inventory carrying costs. Managing inventory is an ongoing process that demands being plugged into the ever-changing market and adjusting for continuous improvement. Product-based retailers of all sizes encounter low profits or a lack of cash flow when inventory is mismanaged.

With so many areas to manage as a small business owner, it’s easy to overlook the importance of accurately managing inventory and knowing where to focus. Here are some common mistakes small retailers make when managing inventory and how an inventory point of sale (POS) system can help you nurture one of the key elements to success and profitability in your retail store.

Manual and Outdated Processes

Some small retailers who have been in the business for many years rely on spreadsheets, experience, and manual order placement to manage their inventory. According to the Retail Council of Canada, many of those who have implemented automated inventory practices “need a new system as they continue to make do with older and outdated systems: ones that have been listed as end-of-life by the provider or were home-grown and lack the ability to easily adopt digital transformation initiatives.” Modern POS inventory software offers real-time visibility of inventory to ensure the most accurate inventory information is available so you can make reliable, accurate, and timely decisions across the entire inventory management process.

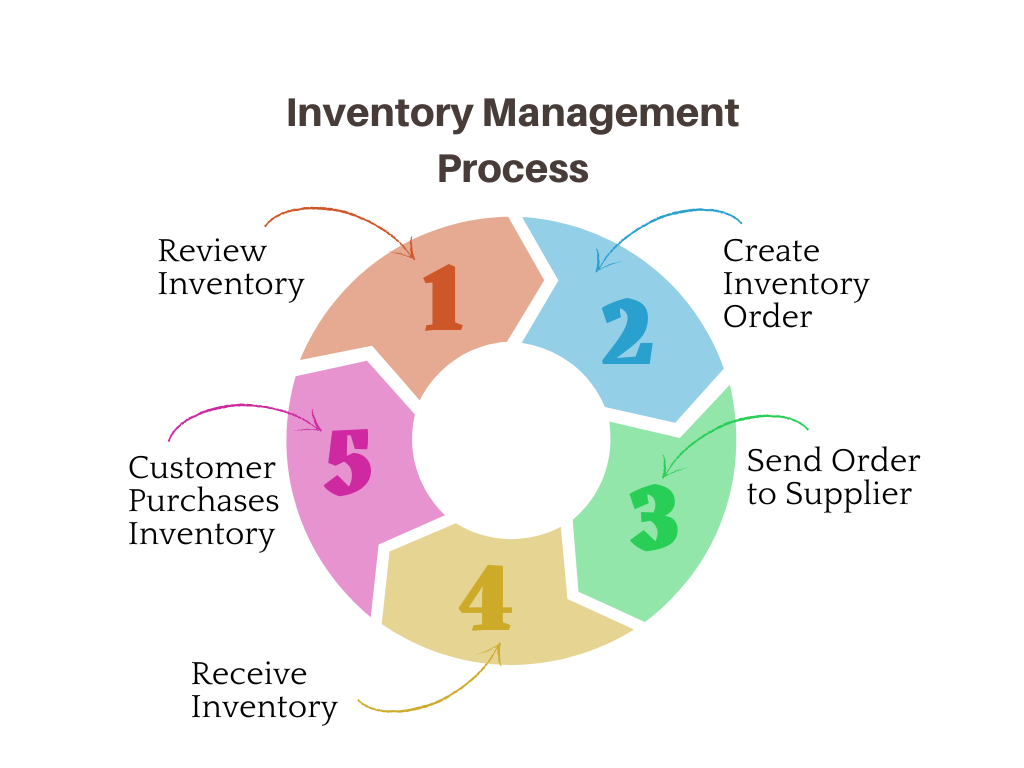

Review Inventory

POS inventory software offers a complete picture of not only the quantity (and cost) of inventory on hand but also on orders from your suppliers. Advanced POS inventory software includes low-stock alerts based on customizable thresholds, so you aren’t caught off guard with low inventory.

Create an Inventory Order

Fully integrated POS inventory software takes the guessing game out of ordering stock and creating purchase orders. With information at hand, such as sales, minimum and maximum quantity on hand, and specific vendor order dates, products can be confidently added to a purchase order with the click of a button.

Send the Order to Your Supplier

With all vendor information stored in one place, sending orders is simplified using POS inventory software, eliminating the error-prone multi-step processes of spreadsheets and manual ordering.

Receive Inventory

Order delivery day is exciting but can also be a great deal of work. With an automated system, items can be quickly received and accurately reconciled using the original purchase order and a barcode scanner. If you’ve purchased products by the case, dividing it up and adding the individual products to inventory is done with just a click of a button. Robust POS inventory software even includes the option to print product or shelf labels while receiving orders. Using one program for all steps not only ensures accuracy but also helps you get products on shelves and available for purchase quicker.

Customer Purchases Inventory

The last but most important step of inventory management is selling products to customers. With the entire process automated, you can be assured that your shelves are fully stocked and products are priced to meet your set target margins. When it comes to product returns (a necessity for providing an all-around positive customer experience), POS inventory software gives real-time updates to your inventory count, with the option to add returned products back to inventory for resale or to track the item as damaged.

Overstocking & Understocking

Knowing just how much inventory to buy is a continuous balance that all retailers face. On one hand, not enough inventory can result in lost sales and unhappy customers. It’s estimated that out-of-stocks are responsible for 39% of consumers leaving a store without making a purchase. With so many shopping options available, customers may lose loyalty if they find your store frequently has products out of stock. On the other hand, an over-supply of inventory has its own costs, including storage, spoilage, and theft. Inventory is expensive to maintain, with annual carrying costs ranging from 20% to 30% of the inventory’s value, and an abundance of inventory may force you to sell at a discount to make room on the shelves before it becomes obsolete deadstock. The most significant problem with overstocking is cash flow management. When valuable cash is tied up in products, it can’t be used to pay bills or to invest in business growth opportunities, such as advertising, new staff, or diversifying products.

POS inventory software can help optimize order quantities, so you have the right amount of inventory to meet customer demand without excess inventory tying up your cash and gathering dust. The key to optimization is understanding key factors such as vendor lead time, inventory turnover, and items with no sales, then adjusting purchasing practices in real-time, a task made much simpler with POS inventory software.

Vendor Requirements and Lead Time

Small business retailers typically select suppliers based on the products and pricing offered. Part of optimizing your inventory management process is understanding vendor requirements, along with knowing when and how much to order at one time. Most vendors have a minimum order quantity to ensure they make a profit with each order. Some minimum order requirements are based on quantity, while others are based on value. As another means to stay profitable, suppliers may also require orders by case only, a factor to weigh when considering cash on hand, how much you expect to sell, and where you will keep items that do not fit on the shelves. A further consideration is vendor lead time, which is the amount of time from when you place the purchase order to when it is delivered to your store to sell. Ongoing supply chain issues have put a wrench into average vendor lead times, but with this information at hand, you have a better idea of how much of an item you will need when it arrives a week (or more) from now.

There is no need to keep all your vendor information memorized or written down in a notebook. POS inventory software stores all this valuable vendor information in an easily accessible, secure program so you are equipped with the information you need. A cloud-based system also means you can access this information from anywhere with an internet connection, meaning you can work from home rather than pulling another all-nighter at your store.

Inventory Turnover

The inventory turnover ratio is the amount of times inventory is sold and replaced during a given time period, such as a month, season, or fiscal year. Evaluating the rate which inventory moves through your store is a litmus test for the effectiveness of your inventory management process. A high inventory turn rate indicates efficiencies in the quantity and type of products you are stocking at your store. A low inventory turn rate signals an overstock of products from ordering too much inventory at one time or low customer interest in the products on your shelves.

POS inventory software can display turn rates at the click of a button, and one with built-in reporting means everything is in one place – no jumping around between apps to find the information you need. With this information at hand, you have a good idea of what products and categories require further assessment in your ordering strategy.

Items with No Sales

As a retail store owner, part of your job is to select products that customers want to buy. Evaluating the products in your store is an ongoing process based on trends and seasons since customer preferences and behaviors are constantly changing. Sometimes products flop, but that doesn’t mean they are a complete loss.

Monitoring items with no sales and adjusting your methods through employee training, merchandising, or pricing will help salvage items that customers aren’t reaching for. If it’s time to discontinue carrying that item, don’t wait until it’s obsolete. Discount the items so that you’re still recovering your costs rather than losing money altogether. POS inventory software can help identify these items based on a selected number of days, so you always have this information at your fingertips.

Decisions Without Data

As a small business owner, it’s easy to get caught up in the day-to-day operations, whether it be resolving the inevitable issues that arise or giving customers a personalized shopping experience. When it comes to the overall health of your business, it’s important to schedule a non-negotiable time to review the bigger picture of your business and ensure your inventory is on track and profitable. When it comes to inventory, two areas to focus on are regular inventory counts and weekly inventory reporting and adjustments.

POS inventory software is an essential tool in helping you make the best decisions for your business. An integrated system that includes POS and inventory controls maximizes the information available to you. For convenience, efficient, and real-time information, a cloud-based POS inventory software solution gives you the tools to manage and evaluate your inventory from anywhere with an Internet connection.

Regular Cycle Inventory Counts

Traditional physical inventory counts typically involve an all-hands-on-deck approach to count all inventory in the store over a short period of time. It might mean pulling an all-nighter or closing your store for the day to get the full count done. Sometimes this is a necessary part of business, but overall, this arduous task can be greatly minimized with cyclical inventory counts.

Cycle inventory counts involve counting a group of inventories – either by category, department, or physical area – on a regular basis and is typically part of an employee’s daily or weekly tasks. Aside from being less disruptive, cycle inventory counts also help to detect inventory discrepancies more quickly. Differences between the quantity of inventory counted and the quantity on record is called shrinkage. While it is a common part of doing business, the less inventory shrinkage, the healthier your bottom line. Shrinkage can result from a variety of reasons, including administrative errors, supplier inaccuracies, employee theft, or shoplifting.

Using modern POS inventory software, stock can be efficiently counted and updated from a handheld device, such as a tablet, eliminating the need for paper printouts and post-count data entry – giving you more time to make adjustments to store procedures and resolve issues for better inventory management.

Weekly Inventory Reports

Intuition and gut feeling may be what is required as you start your business, but as you gain sales data, it’s imperative for ongoing success to review what is working and what isn’t at your store. Profitability doesn’t come from doing what all the other local shops are doing, it comes from finding what is working based on your store and customer base, then making small adjustments continuously. POS inventory software collects and sums up your inventory data to give you a valuable picture of the health of your store without feeling overwhelmed.

A Profit Analysis Report displays the Inventory Turn Rate and Gross Profit Return on Investment (GPROI) as well as sales, profits, margins, quantity on hand, and more – all in one report. It gives an overall picture of profit margins, what is selling, what to buy more of, and what departments or categories perform best so you know what to focus on for future purchases and new products. POS inventory software with reporting is a guide to help point your business in the right direction for optimal performance.

Inventory is at the heart of all product-based retail stores. Ongoing management and evaluation of the products sold in your store is necessary to combat the pitfalls of inventory mismanagement which include low profits or lack of cash flow. Robust POS inventory software that includes a fully integrated point of sale and inventory management system means you have access to accurate and real-time data without the gaps of third-party integrations. It also means you pay only one fee for the entire suite of inventory management processes and can have all your questions answered from one company. Future-proof your business with POS inventory software.